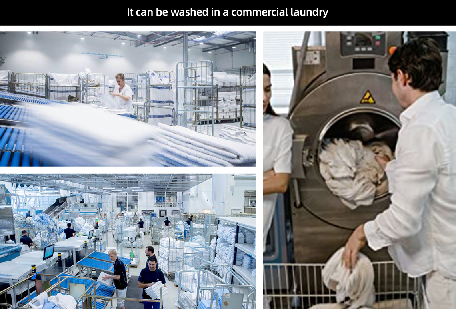

In terms of maintenance, a 28cm fitted sheet is no more challenging than a regular one

Charcoal sheets are not just for visual art

Another critical factor in impeller design is the material used for construction. Sewage pump impellers can be made from various materials, including cast iron, stainless steel, or thermoplastics. The choice of material depends on the chemical composition of the waste being pumped. For example, stainless steel impellers offer excellent corrosion resistance, making them suitable for applications involving harsh chemicals.

Propeller pumps are a crucial element in the field of fluid dynamics, primarily utilized for their efficiency in moving large volumes of fluids. These pumps operate on a simple principle they use a rotating propeller to impart energy to the liquid, creating a flow that can be directed to various applications. This article explores the various uses and advantages of propeller pumps.

b. Selection Software:

Sand and Gravel Separation in Quarrying with Horizontal Slurry Pumps

- Most slurry pump manufacturers provide selection charts that correlate slurry characteristics and operating conditions with suitable pump models.

Understanding the Importance of Impeller Wear Ring Maintenance

- Review the performance curves for the selected pump models to ensure they meet your flow rate and head requirements.

Materials: Liners are often made from high-chrome alloys, rubber, or other wear-resistant materials.

Regular monitoring and maintenance of AH Slurry Pump parts are crucial for sustaining the pump’s performance and efficiency. This includes inspecting components such as the impeller, casing, and wear plates for signs of wear or damage. Replacing worn parts promptly helps maintain the pump’s performance and prevents more extensive damage that could lead to costly repairs or replacements. Additionally, monitoring the pump’s operational parameters, such as vibration and noise levels, can provide early warning signs of potential issues. By keeping AH Slurry Pump parts in optimal condition, operators can ensure consistent performance and prolong the lifespan of the horizontal centrifugal slurry pump.

Conclusion

Function: Seals prevent slurry from leaking out of the pump and protect the internal components.

Monitoring Wet Parts for Optimal Pump Performance

Understanding the Importance of Impeller Wear Ring Maintenance

4. Shaft Sleeves

- Head: Calculate the total head required (static head plus friction losses).

Function: The backplate provides structural support and helps in mounting the pump.

Impellers are the rotating parts of sewage pumps that convert rotational energy from the motor into kinetic energy within the fluid. This transformation occurs through the design of the impeller blades, which are shaped to create a flow of water, pushing it outwards through the volute or the casing. The design of the impeller directly affects the pump's efficiency, capacity, and performance.

Types:

a. Manufacturer’s Support:

1. Impeller

Comparing Vertical and Horizontal Pumps: Key Considerations

SPR slurry pumps are specifically designed for handling slurry in applications where high liquid levels are a concern. These pumps are engineered to operate efficiently in environments where the pump must remain submerged for extended periods. The vertical design of SPR slurry pumps allows them to function effectively in deep pits and sumps, where other pump types might struggle. By optimizing the design to handle high liquid levels, SPR slurry pumps provide reliable performance in challenging conditions, ensuring that slurry is effectively managed and transported, even in the most demanding deep pit applications.

The shaft transmits power from the motor to the impeller, while the bearing assembly supports the shaft and allows it to rotate smoothly. The durability of these components is essential, as they must endure continual mechanical stress and the harsh conditions present within the slurry.

Wear Factors: Seals can degrade over time due to contact with abrasive slurry and need regular replacement.

5. Shaft and Bearing Assembly

Horizontal inline centrifugal pumps are among the most versatile pumps available, widely used across industries for their reliability and ease of maintenance. Unlike vertical pumps, these pumps are installed horizontally, which typically makes them easier to service and maintain. The horizontal design allows for more straightforward access to the pump’s internal components, which can be a significant advantage in applications where regular maintenance is required. Additionally, horizontal inline centrifugal pumps are capable of handling a wide range of fluid viscosities and flow rates, making them suitable for various industrial processes. Their versatility and robust construction make them a popular choice for many fluid handling applications.

Understanding the Role of Propeller Pumps in Various Applications

- Decide between direct drive, belt drive, or variable speed drive based on your application needs.

- Volute Liners: Protect the pump casing in the volute section.

Understanding the components of the wet end of a slurry pump is vital for anyone involved in industries that rely on such equipment. Proper maintenance and selection of high-quality parts can significantly enhance the efficiency and lifespan of a slurry pump, reducing operational costs and minimizing downtime. By focusing on the critical wet end parts—impeller, casing, wear plates, flanges, and the shaft assembly—operators can ensure their pumps perform reliably in challenging environments.

3. Casing

b. Impeller Design:

- Most slurry pump manufacturers provide selection charts that correlate slurry characteristics and operating conditions with suitable pump models.

b. Impeller Design:

- Throat Bush: Protects the area around the impeller eye where the slurry first enters.